- Q What are tube materials?

- A

There are two main options, which are carbon steel galvanized and stainless steel cladding. On the curve conveyor, user can choose PU,PP, and PVC.

.jpg)

- Q The choice of roller length

- A

400mm~1800mm are available for customization.

.jpg)

- Q How long is connector wire?

- A

400mm.

.jpg)

- Q On BLDC Power Roller with double round groove design, does O-rings affect transportation and the size of box?

- A

No, the O-ring won't affect the transportation and the size of box.

.jpg)

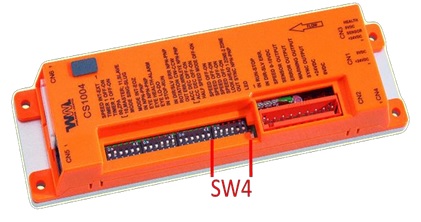

- Q Control card - ZPA:Master/Slave mode

- A

When setting in this mode, the zone has two motorized rollers to share the loading and the Master will command the logic of motion. On the Master/Slave mode, two BLDC Power Rollers share one sensor. Master/Slave mode must be under the same speed for balancing current and speed.

.jpg)

- Q How does user adjust BLDC Power Roller speed?

- A

User can change the speed by adjusting DIP switch on the control card or external controller.

.jpg)

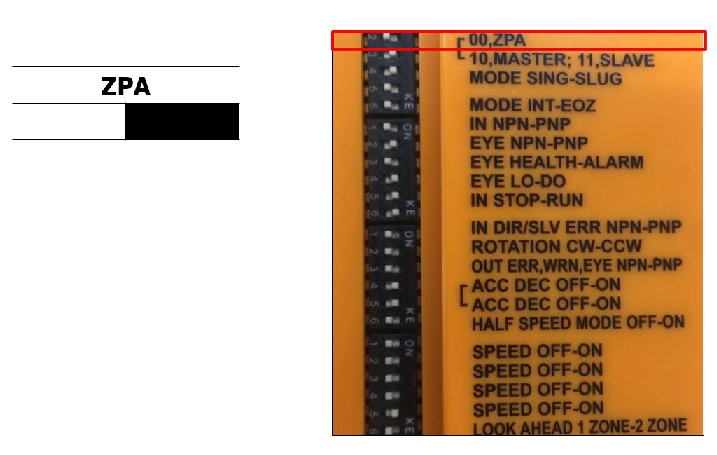

- Q Control card - How does user adjust ZPA mode?

- A

User can choose ZPA mode by adjusting DIP switch on the control card.

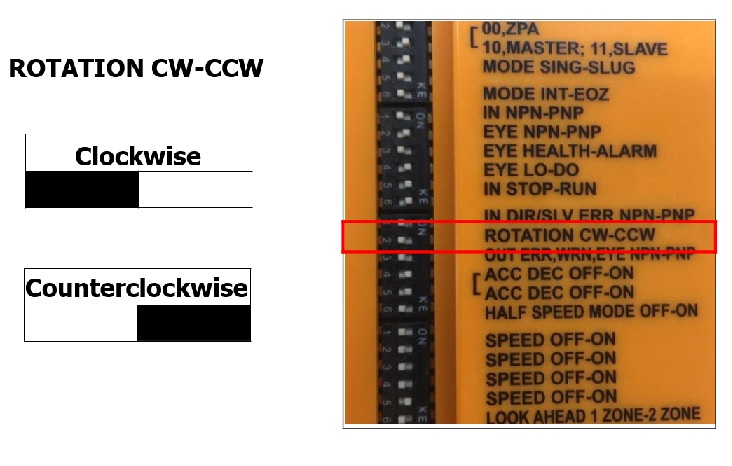

- Q Control card - How does user switch the clockwise rotation to counterclockwise rotation?

- A

User can adjust the rotation by DIP switch on the control card or external controller.

- Q How does BLDC Power Roller detect objects and start moving?

- A

A BLDC Power Roller set includes sensor, intelligent control card, and power roller. The Intelligent control card will activate the BLDC Power Roller while sensor detect the object.

- Q What kind of BLDC Power Roller should be used on incline or decline conveyor? What kind of BLDC Power Roller should be used on incline or decline conveyor?

- A

We suggest user apply high torque one on the incline zone, and brake one on the decline.