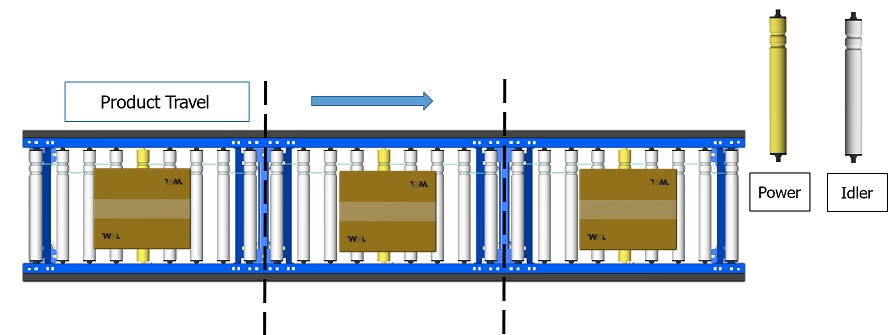

- Q What different is the way of transportation between BLDC Power Roller and AC Conventional Conveyor ?

- A

.jpg)

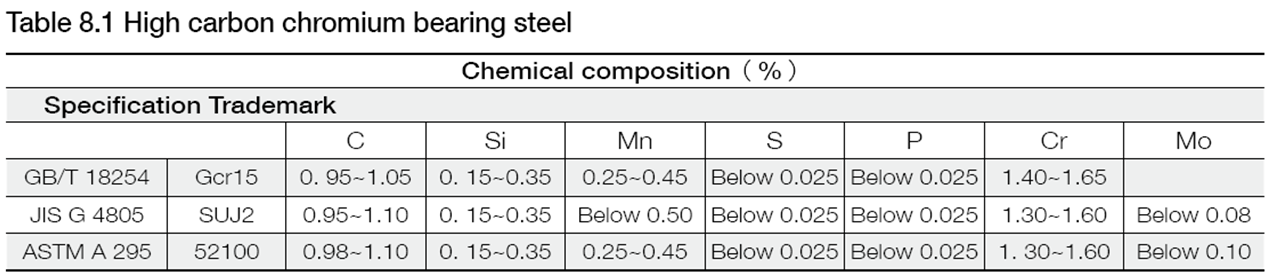

- Q Bearings Materials

- A

The bearings and its rings and rolling elements are primarily made of high carbon chrome steel. Most of the bearings are made of SUJ2, which is equivalent to AISI52100 in the U.S.A. and DIN 100Cr6 in Germany.

For some request, we will use stainless steel or brass with fine anti-corrosive performance.

Mostly, the pressed cages of bearings are made of carbon steel. It also can be request to be made of stainless steel and brass.

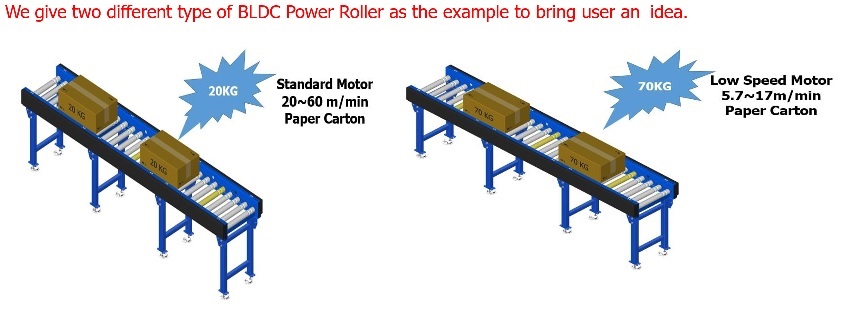

- Q What is the maximum of transportation weight?

- A

- Q How does each control card communicate?

- A

On our control card design, user can use RJ45 communicate wire to connect control cards.

- Q What is the range of ambient temperature in operation?

- A

Temperature: 0°C~40°C (32°F~104°F).

- Q How quick is the limit for interval operation of power roller?

- A

The shortest frequency for ON and OFF:

1.5 seconds for ON; 0.5 second for OFF.

- Q What is ZPA (Zero Pressure Accumulation)?

- A

ZPA conveyors consists of zones has its individual electronic control system. Each zone has one power roller connects with other non-power roller. The zone will stop if downstream zone is occupied. The zone only activates if next zone is clear.

- Q What is the advantages of choosing ZPA?

- A

.jpg)

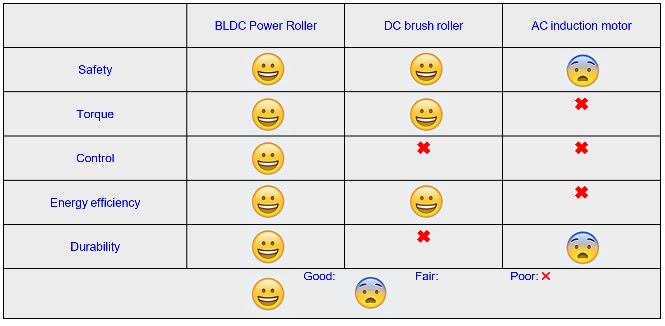

- Q What are the advantages of BLDC Power Roller compare with other kinds of motor?

- A

- Q What kind of transmission (drive head) should user choice?

- A

.jpg)