- Q What kind of BLDC Power Rollers should user choose?

- A

Our experts can help user choose the appropriated BLDC Power Roller by giving following information to us.

•Speed requirement.

•The material of contact surface.

•The dimension and weight of transportation.

•Environment condition.

•Throughput requirement.

.jpg)

- Q What are tube materials?

- A

There are two main options, which are carbon steel galvanized and stainless steel cladding. On the curve conveyor, user can choose PU,PP, and PVC.

.jpg)

- Q The choice of roller length

- A

400mm~1800mm are available for customization.

.jpg)

- Q How long is connector wire?

- A

400mm.

.jpg)

- Q On BLDC Power Roller with double round groove design, does O-rings affect transportation and the size of box?

- A

No, the O-ring won't affect the transportation and the size of box.

.jpg)

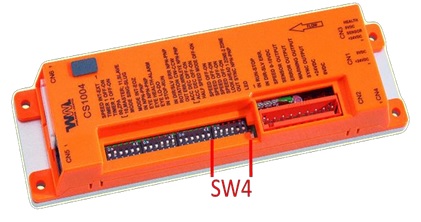

- Q Control card - ZPA:Master/Slave mode

- A

When setting in this mode, the zone has two motorized rollers to share the loading and the Master will command the logic of motion. On the Master/Slave mode, two BLDC Power Rollers share one sensor. Master/Slave mode must be under the same speed for balancing current and speed.

.jpg)

- Q How does user adjust BLDC Power Roller speed?

- A

User can change the speed by adjusting DIP switch on the control card or external controller.

.jpg)

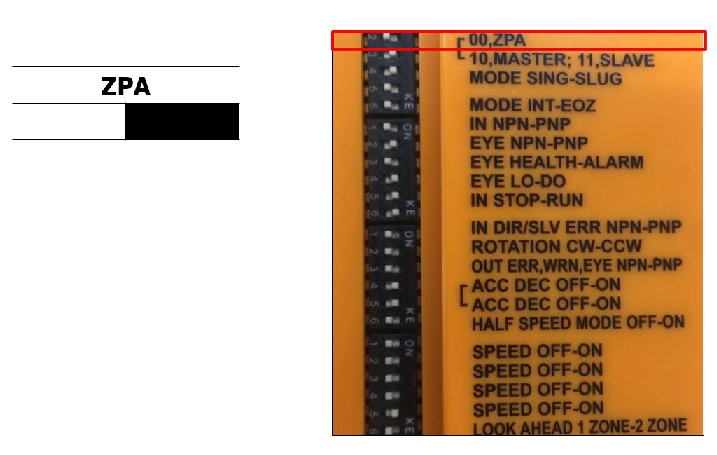

- Q Control card - How does user adjust ZPA mode?

- A

User can choose ZPA mode by adjusting DIP switch on the control card.

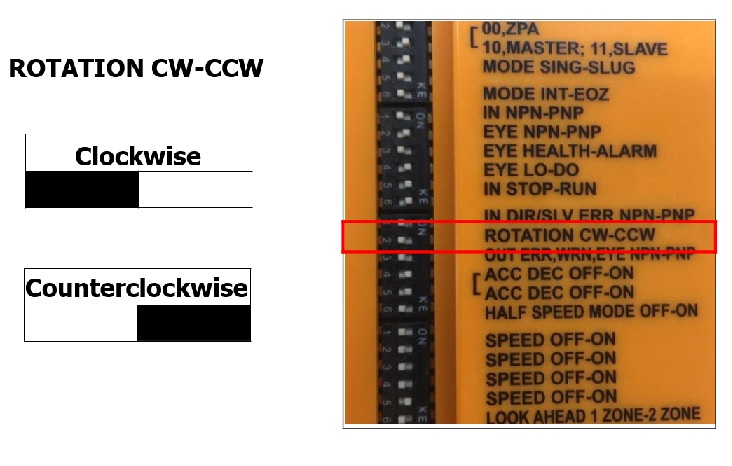

- Q Control card - How does user switch the clockwise rotation to counterclockwise rotation?

- A

User can adjust the rotation by DIP switch on the control card or external controller.

- Q The characteristics of Deep Groove Ball Bearings

- A

Deep groove ball bearings are the most common type of rolling bearings and very widely used. A deep groove is formed on each inner and outer ring of the bearing enabling them to sustain radial and axial loads in either direction as well as the complex loads which result from the combination for high speed applications.

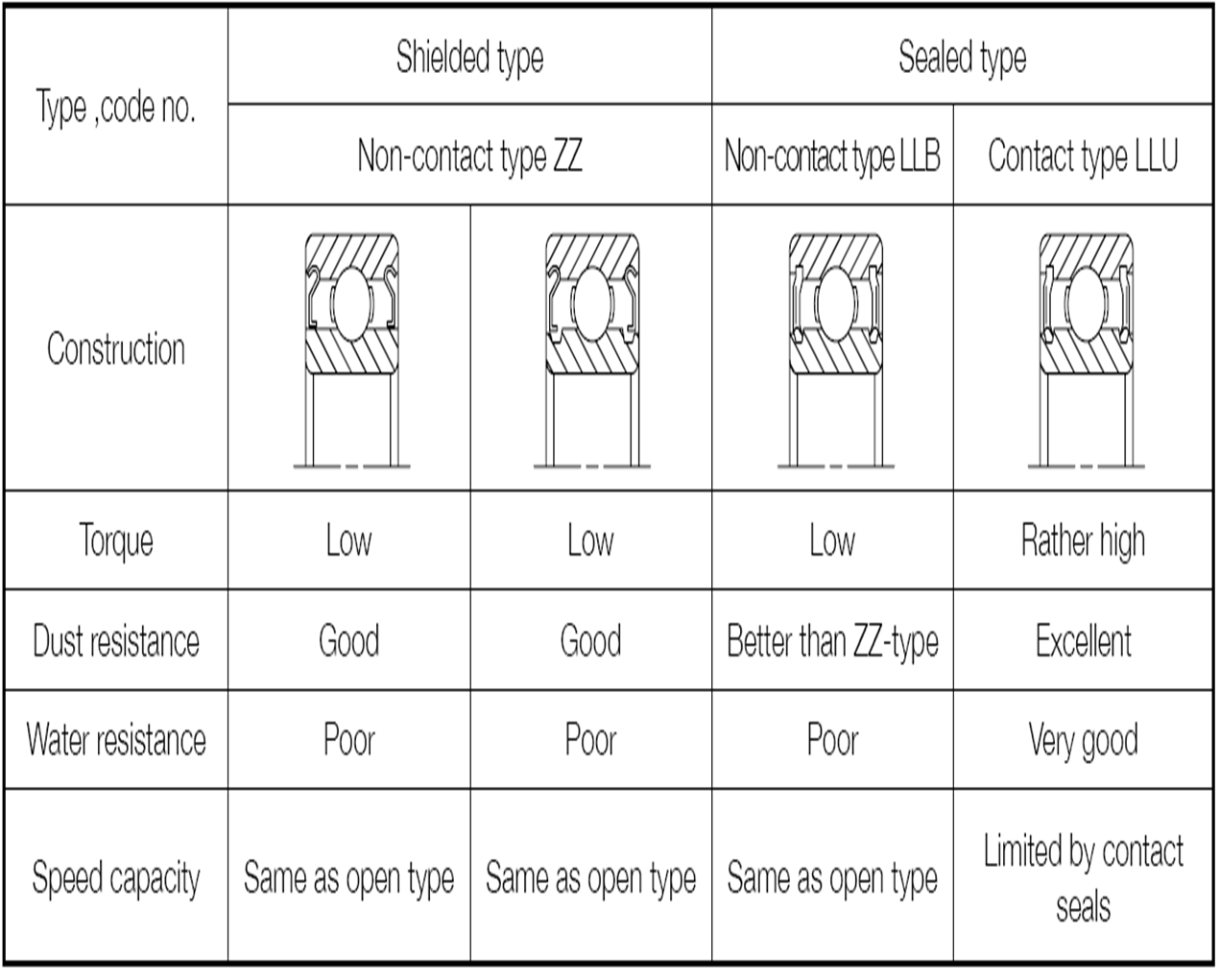

Table 1 Sealed Ball Bearings: Construction and Characteristics

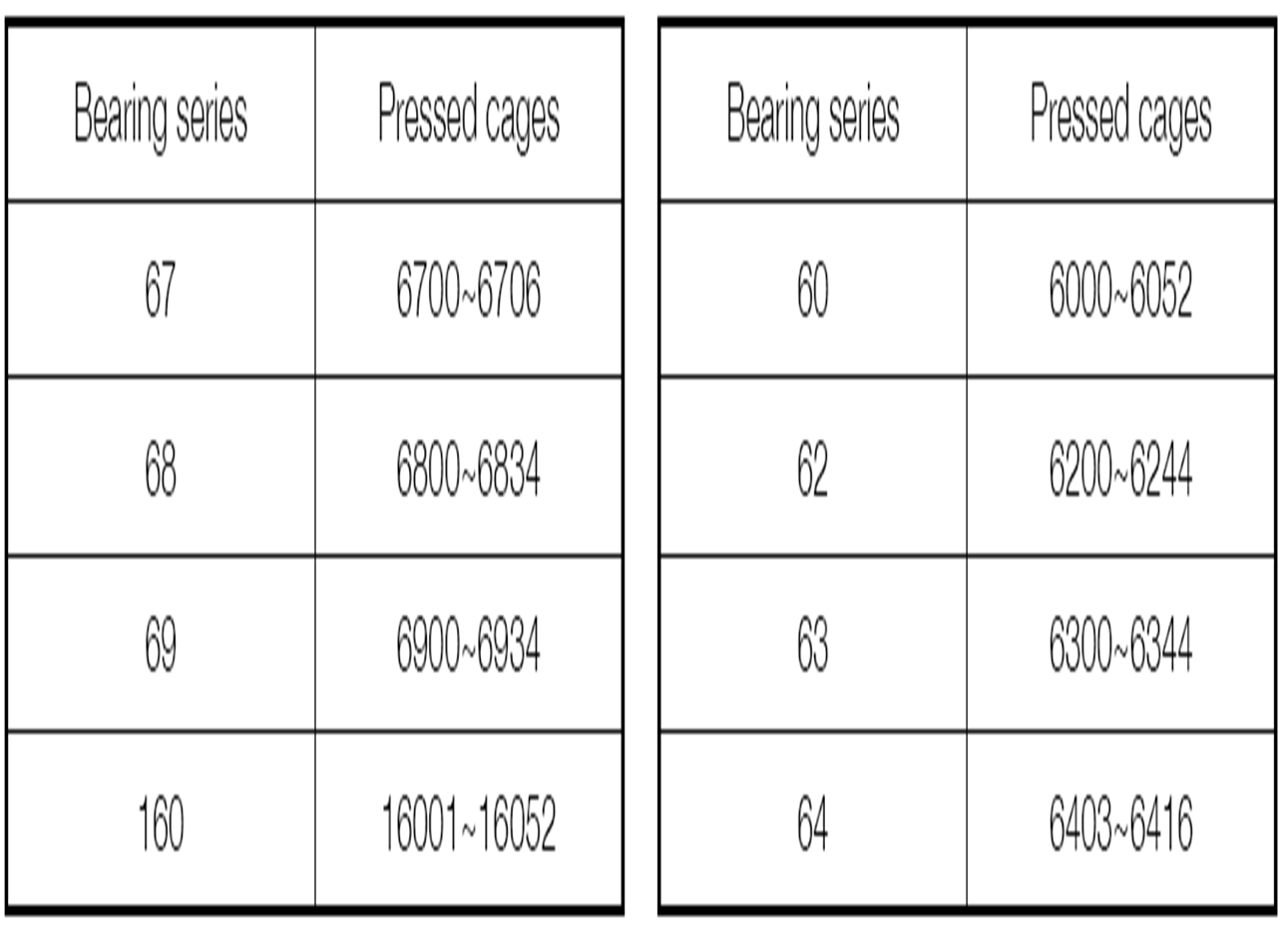

Pressed cages are usually used in deep groove ball bearings and high-speed bearings. As shown on Table 2

Table 2 Standard cage for deep groove ball bearings

Rolling bearings is commonly composed of ring, roller, and cage. It is divided into ball bearings and roller bearing according to the rolling category. The characteristics are as below:

1. It is equipped with high standard and ample specifications with fine interchangeability.

2. Commonly it can simultaneously bear radial load and axial load.

3. it is applicable for use in high and low temperature.

4. it is fit for use in high speed conditions.

Single-row deep groove ball bearing is the structure with the widest application in rolling bearings. The bearings can simultaneously bear radial and zxial load. It is fit for use in the occasions such as high-speed rotation, low noise, and etc.